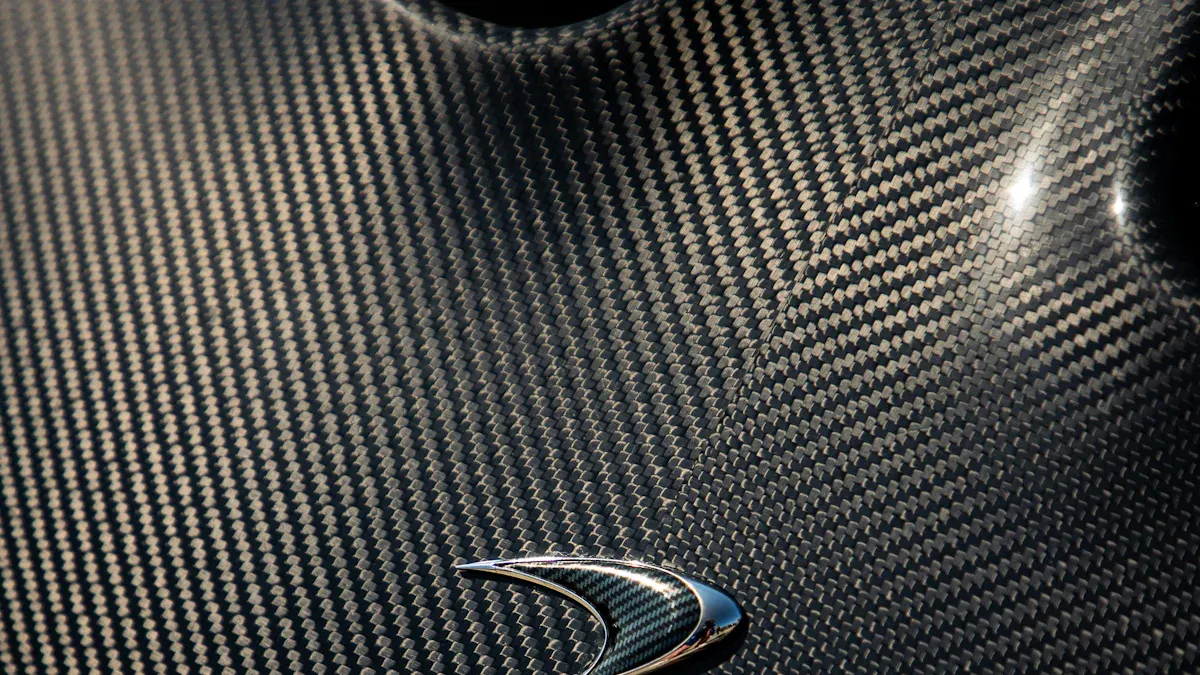

Complete Guide to Applying Carbon Fiber Paint on Motorcycle Fairings

Painting carbon fiber motorcycle fairings requires special attention. You work with a material that can trap air, which may cause pinholes or bubbles if not prepared well. Using the right carbon fiber paint helps prevent adhesion problems, especially when you clean and sand the surface carefully. Some riders notice yellowing or fading on their fairings over time because the sun affects the resin. You can avoid this by applying a strong clear coat with UV protection. Orange peel texture sometimes appears if you use the wrong spray settings or paint thickness. Light, thin coats of carbon fiber paint keep your fairings looking sharp without adding extra weight.

Why Carbon Fiber Paint Is Unique

Properties of Carbon Fiber Fairings

You work with a material that stands out from plastic or metal. Carbon fiber fairings combine strength, lightness, and resistance to many chemicals. The table below shows how carbon fiber compares to other common fairing materials:

| Property Category | Carbon Fiber Characteristics | Comparison to Plastic/Metal Fairings |

|---|---|---|

| Density | Very low density (~1.6 g/cm³), significantly lighter than steel and aluminum | Plastic and metals generally heavier, increasing overall weight |

| Molecular Structure | Carbon atoms bonded in hexagonal lattice, providing exceptional strength and flexibility depending on fiber orientation | Plastics lack crystalline strength; metals have different atomic bonding and higher density |

| Tensile Strength | High tensile strength (3.5 to 6.0 GPa), comparable or superior to steel on a strength-to-weight basis | Plastics have lower tensile strength; metals are strong but heavier |

| Compressive Strength | High compressive strength, variable with fiber orientation | Plastics can deform under load; metals generally strong but heavier |

| Elastic Modulus | Very high (200 to 600 GPa), indicating stiffness | Plastics are less stiff; metals vary but generally less stiff per weight |

| Chemical Resistance | Highly resistant to corrosion, acids, bases, solvents; does not rust or oxidize | Metals prone to rust/oxidation; plastics can degrade chemically |

| Thermal Properties | Does not melt under normal conditions; decomposes at very high temperatures (~3000°C in inert atmosphere); anisotropic thermal conductivity | Plastics melt at low temps; metals conduct heat isotropically and can oxidize at high temps |

| Electrical Conductivity | Electrically conductive due to graphitic structure | Plastics are insulators; metals conductive but prone to corrosion |

| Flexibility | Fiber orientation controls stiffness and flexibility; can be tailored for stiffness or impact resistance | Plastics flexible but weaker; metals less flexible and heavier |

These properties make carbon fiber fairings ideal for motorcycles. You get a lightweight part that stays strong and resists damage from chemicals or weather.

Challenges When Using Carbon Fiber Paint

Painting carbon fiber fairings brings unique challenges. The surface energy of carbon fiber composites starts low, which makes paint adhesion difficult. You need to treat the surface to improve how well the paint sticks. Plasma treatment works best because it increases the surface energy and helps the paint bond both chemically and physically.

When you prepare your fairings, avoid stripping off the clear coat completely. This can damage the gelcoat and expose the carbon fibers. Instead, lightly sand the surface until it looks hazy. This step helps the new paint grip better.

Tip: Always use primers made for carbon fiber, such as urethane or epoxy primers. Regular primers do not bond well and can cause peeling.

Common issues you might face include:

- Poor adhesion if you skip surface prep or use the wrong primer.

- Weakening the fairing by over-sanding and exposing the weave.

- Fading or yellowing from UV exposure if you skip a UV-protective clear coat.

- Hiding cracks with paint, which can lead to unnoticed damage.

You must use the right products and techniques to get a durable, professional finish with carbon fiber paint.

Surface Preparation for Carbon Fiber Paint

Cleaning and Degreasing Fairings

You need to start with a clean surface before you paint. Dirt, oil, and dust can stop the paint from sticking well. Follow these steps to get your fairings ready:

- Wipe the carbon fiber with isopropyl alcohol and a lint-free cloth. This removes oils and dust. Studies show that proper cleaning can improve paint adhesion by up to 50%.

- After cleaning, use a tack cloth or vacuum to pick up any leftover dust. Even small particles can cause paint defects.

- Use an air blower to clean hard-to-reach spots. Make sure every part of the fairing is free from debris.

Tip: Always use clean gloves when handling the fairings after cleaning. This prevents new oils from your hands from getting on the surface.

Sanding and Smoothing the Surface

Sanding is a key part of preparing the surface for carbon fiber paint. You want to create a texture that helps the paint stick, but you do not want to damage the carbon fiber weave.

- Start with 220-grit sandpaper to lightly scuff the surface.

- Move to 400-grit sandpaper for a smoother finish. This step helps the paint bond better.

- For any major imperfections, use 80-120 grit sandpaper sparingly. Avoid sanding too deep.

- Wet sanding works best. It keeps the surface cool and prevents damage.

- After sanding, remove all dust with a tack cloth and air blower.

Preparing the surface with the right sandpaper grit ensures a strong bond and a smooth look.

Inspecting for Damage or Imperfections

Before you paint, check the fairings for any flaws. Look for swirls, haze, or holograms. These marks often come from the factory and can show through the paint if you do not fix them.

- Use a bright light to spot imperfections.

- If you find swirls or haze, polish them out before painting.

- Check for cracks or chips. Repair these before you continue.

Preparing the surface by fixing these problems gives you a better final result and helps your carbon fiber paint last longer.

Priming Carbon Fiber Fairings

Choosing a Compatible Primer for Carbon Fiber Paint

You need to pick the right primer before you paint your motorcycle fairings. Epoxy primers work best for carbon fiber because they bond well and help the paint stick. These primers have strong penetration ability, so they reach deep into the surface. You get better adhesion and a longer-lasting finish. Epoxy primers also resist aging, water, and chemical corrosion. After curing, they show toughness and elasticity, which helps protect your fairings from cracks or chips.

When you shop for a primer, look for one made for plastics and composite materials. A carbon fiber-safe primer will give you the best results. Always clean the fairing surface before you apply primer. Dirt, grease, or leftover sanding dust can stop the primer from sticking. Use a lint-free cloth and isopropyl alcohol to wipe down the fairings. This step helps you avoid problems later.

Tip: Choose a high-quality adhesive primer that lists carbon fiber compatibility on the label. This ensures your paint job will last and look great.

Applying Primer Evenly

You want to apply the primer in thin, even coats. Thick layers can cause drips or uneven surfaces. Hold the spray gun or can about 6 to 8 inches from the fairing. Move your hand in smooth, steady motions. Overlap each pass by about 50% to avoid missed spots.

Let each coat dry before you add another. Most primers need 10 to 15 minutes between coats. Check the instructions on your primer for the best results. Usually, two to three coats give you a solid base for your carbon fiber paint.

After the final coat dries, inspect the surface. Look for any runs, bubbles, or rough spots. If you see any, lightly sand the area with 400-grit sandpaper and wipe it clean. This step helps you get a smooth, professional finish when you start painting.

Selecting Carbon Fiber Paint and Materials

Types of Paint Suitable for Carbon Fiber

When you start choosing the right paint for your motorcycle fairings, you need to know which types work best on carbon fiber. Not all paints stick well to this material. You want paint that bonds to the resin surface and stays strong over time.

Matte finishes on carbon fiber panels allow paint and clear coats to stick better. Gloss finishes look shiny but can show scratches and chips more easily. Before you paint, always sand the surface. This step helps the paint grip the fairing and prevents peeling.

You should look for these paint types:

- Etching primers, like Rustoleum etching primer, work well on carbon fiber and other composites. They help the paint bond to the surface.

- Clear coats and clear candy color paints let you keep the carbon fiber texture while adding color or shine.

- Urethane and epoxy-based paints are also good choices because they offer strong adhesion and resist chemicals.

Note: Painting carbon fiber is similar to painting fiberglass. You always paint on the resin surface, not directly on the fibers.

Recommended Brands and Products

You have many options when it comes to brands and products for carbon fiber paint. Some brands make products that work especially well on composite materials. Here are some top picks:

- Rustoleum Etching Primer: This primer prepares the surface and helps the paint stick. It is easy to find and works well for DIY projects.

- Dupli-Color Perfect Match: This paint offers a wide range of colors and works well with primed carbon fiber surfaces.

- SprayMax 2K Clear Coat: This clear coat gives a glossy, durable finish and protects against UV rays.

- House of Kolor Kandy Colors: These paints add vibrant color while letting the carbon fiber weave show through.

When choosing the right paint, always check the label for compatibility with carbon fiber or composite materials. Using the right products helps you get a finish that lasts and looks professional.

Application Techniques for Carbon Fiber Paint

Spray Painting Methods and Equipment

You need the right tools and methods to get a smooth finish when painting carbon fiber. Spray painting works best for motorcycle fairings because it gives you even coverage and helps avoid brush marks. You can use either a spray gun or aerosol cans. A spray gun offers more control and a finer mist, but aerosol cans are easier for beginners.

Here are some tips for choosing your equipment:

- Use a high-volume, low-pressure (HVLP) spray gun for professional results. HVLP guns reduce overspray and waste.

- Pick a nozzle size between 1.2 mm and 1.4 mm for base coats and clear coats.

- If you use aerosol cans, shake them well for at least two minutes before spraying. This helps mix the paint and prevents clogging.

- Always test your spray pattern on a piece of cardboard before you start applying the paint to your fairings.

Tip: Wear a respirator mask and work in a well-ventilated area. Paint fumes can be harmful if you breathe them in.

Applying Thin, Even Coats

You want to apply the paint in thin, even layers. Thick coats can cause runs, drips, or an uneven surface. Thin coats dry faster and help you build up color slowly. This technique also keeps the fairings light, which is important for performance.

Follow these steps for best results:

- Hold the spray gun or can about 6 to 8 inches from the surface.

- Move your hand in steady, overlapping strokes. Start spraying before you reach the fairing and stop after you pass the edge.

- Let each coat dry for 10 to 15 minutes before adding the next one. This prevents the paint from sagging or pooling.

- Apply two to three coats for solid coverage. If you want a deeper color, you can add more coats, but always keep them thin.

Remember: Applying the paint in thin layers helps you avoid orange peel texture and gives you a smooth, glossy finish.

Managing Temperature and Humidity

Temperature and humidity play a big role in how your paint job turns out. You need to control these factors to get the best results when you paint carbon fiber.

- Work in a space where you can manage temperature and humidity. Avoid painting in hot, cold, rainy, or humid weather. These conditions can cause the paint to dry too fast or too slow, leading to poor adhesion and surface defects.

- Keep your workspace dry, cool, and well-ventilated. Do not paint in direct sunlight or near strong drafts. This helps the paint cure evenly and prevents dust from landing on wet surfaces.

- Let your painted fairings dry for at least 24 hours before handling them. Full curing can take several days to a week. Thicker coats and top layers need more time to cure, especially if the temperature or humidity is not ideal.

- Store your painted parts away from sudden temperature changes and high humidity. This keeps the finish looking good and prevents problems like swelling or surface waviness.

You should know that temperature affects the curing process of carbon fiber paint. When you increase the temperature by 10°C, the chemical reactions speed up by up to three times. Some professional shops use carbon fiber heating elements to dry paint in just two minutes, compared to 30 minutes with regular methods. Humidity also matters. High humidity can cause defects like print through, swelling, or uneven surfaces. Try to keep the relative humidity below 85% during curing. This helps the paint bond well and keeps your fairings strong.

Note: Longer curing times improve the durability of your paint job. Do not rush the process. Patience gives you a finish that lasts.

Clear Coating Over Carbon Fiber Paint

Importance of Polyurethane Clear Coat

You need to protect your carbon fiber paint job with a strong clear coat. Polyurethane clear coat works best for this. The resin in carbon fiber can absorb water and break down if you leave it unprotected. When you use a polyurethane clear coat, you seal the surface. This stops water and oxygen from reaching the resin. The clear coat also blocks UV rays from the sun, which keeps your fairings from fading or turning yellow. You can polish and maintain this layer just like regular car paint. This is why sealing with a high-quality clear coat is so important for your motorcycle fairings.

Remember: The importance of a protective clear coat goes beyond looks. It keeps your carbon fiber strong and helps your paint last longer.

Types of Clear Coats for Carbon Fiber

You have a few choices when picking a clear coat for carbon fiber. Most riders choose a high-quality automotive-grade clear coat. Polyurethane clear coats give you the best mix of protection and shine. They are flexible, so they move with the fairing and do not crack easily. Some clear coats come with extra UV blockers. These help your fairings stay bright and glossy even after long rides in the sun. Avoid gelcoats for this job. Gelcoats are thick and hard, but they do not work well over carbon fiber in motorcycle or car applications.

Application Tips for Clear Coat

You want your clear coat to look smooth and even. Follow these steps to get the best results:

- Sand the painted surface with 220-400 grit sandpaper to remove bumps.

- Switch to finer sandpaper, like 1000-1500 grit, for a glassy finish.

- Use wet sanding to keep the surface cool and protect the carbon fiber weave.

- Hold your spray gun or can 6 to 8 inches from the fairing.

- Spray in thin, even coats. Let each coat dry before adding the next.

- Check your work under bright light to spot any flaws.

- After the clear coat dries, polish with a soft pad and fine polish to boost the shine.

Tip: Always use gentle pressure when sanding or polishing. Carbon fiber clear coats are softer than regular paint, so take your time.

Curing and Finishing Carbon Fiber Paint

Proper Drying and Curing Times

You need to let your carbon fiber paint dry and cure fully before you touch or polish it. Paint dries on the surface in a few hours, but curing takes longer. Curing means the paint and clear coat harden all the way through. Most paints need at least 24 hours to dry to the touch. For best results, wait 5 to 7 days before you polish or add any protective layers. If you rush this step, you can damage the finish or leave marks. Keep your fairings in a clean, dust-free area while they cure. Try to keep the temperature steady and avoid high humidity. This helps the paint bond well and last longer.

Tip: Always check the paint and clear coat labels for exact drying and curing times. Some products may need more or less time.

Polishing for a Glossy Finish

After the paint cures, you can polish your fairings to get a deep, glossy shine. Use fine-cut automotive polishes made for clear coats. Start with the least aggressive polish, like a finishing polish, to remove light swirls and boost gloss. Look for polishes with these features:

- Diminishing abrasives that break down as you polish, which helps prevent scratches.

- Good lubrication to stop heat and friction from building up.

- Labels that say "safe for clear coats" to protect your finish.

- Water-based formulas for a true shine without fillers.

- Silicone-free options, which are often better for long-term care.

Work in small sections and test the polish in a hidden spot first. Avoid harsh rubbing compounds or metal polishes. These can scratch or dull your clear coat. Always use a soft pad and gentle pressure.

Adding Protective Layers

You can make your carbon fiber paint last even longer by adding extra protection. Ceramic coatings give you a tough, long-lasting shield that resists water, dirt, and UV rays. Paint Protection Film (PPF) works like a clear wrap. It guards against scratches and chips. Some films even come with warranties. For regular care, wash your fairings every two weeks and use a gentle wax. If you use a 2K clear coat, remember to wear a respirator because the chemicals can be harmful. These steps help keep your motorcycle fairings looking new and shiny for years.

Common Mistakes and Troubleshooting with Carbon Fiber Paint

Adhesion Problems

You may notice that paint adhesion sometimes fails on carbon fiber fairings. This happens for several reasons:

- Mold release agents, often containing silicones, can stay on the surface and block paint adhesion.

- If you do not sand enough, the surface stays too smooth, and the paint cannot grip.

- Low surface wettability means the paint cannot spread and bond well.

To prevent these issues, always clean the fairing thoroughly to remove all contaminants. Sand the surface to create enough roughness for better contact. You can also use treatments like plasma or laser to boost surface energy and help paint adhesion. If you see layers peeling or delaminating, check for dust, oil, or poor curing. Fixing these problems early keeps your fairings strong and safe.

Tip: Use a primer made for carbon fiber to improve paint adhesion and avoid peeling.

Pinholes and Surface Defects

Pinholes and small pits can ruin the look of your paint job. These defects often come from trapped air, fast temperature changes, or gas generation during curing. The table below shows common causes and solutions:

| Cause | What Happens | How to Fix |

|---|---|---|

| Air trapped under the surface | Bubbles form and create pinholes | Use grooved adhesives or separator films to let air escape |

| Volatiles in the material | Bubbles expand and burst | Use proper cure cycles and lower temperatures |

| Gas from material reactions | Extra gas causes more pinholes | Use breather materials and special tapes |

| Fast temperature rise during curing | Air gets trapped against the tool | Follow slow, steady temperature ramps |

Always follow the recommended curing process and use the right materials to keep your paint smooth.

Yellowing and UV Damage

Yellowing and fading can make your fairings look old. Sunlight causes chemical changes in the paint and resin, leading to yellow spots and loss of gloss. Low-quality films without UV blockers make this worse. Road chemicals and harsh cleaners can speed up the damage. If you trap air or dirt under a protective film, yellowing can happen faster.

To protect your fairings, use high-quality paint protection films with UV resistance. Make sure you install them carefully to avoid bubbles and dirt. Clean your fairings with products made for carbon fiber. Check your fairings often for early signs of yellowing. Quick action helps you keep your paint looking fresh.

Note: Moisture and temperature changes can also speed up yellowing, so store your motorcycle in a dry, shaded place when possible.

Orange Peel Texture

Orange peel texture makes your painted fairings look bumpy, like the skin of an orange. This problem often happens when the clear coat does not level out smoothly. You might see this after a factory paint job or if you spray too thickly. Orange peel does not just affect how your motorcycle looks. It can also make the surface harder to clean and polish.

To fix orange peel on carbon fiber paint, follow these steps:

- Wet-sand the surface with very fine sandpaper, such as 3000 grit. Use plenty of water or a little diluted shampoo for lubrication.

- Use a dual-action sander if you have one. Keep your pressure light and even to avoid sanding through the clear coat.

- Check your progress often. Make sure you sand all areas evenly.

- After sanding, polish the surface with a heavy-cut polish like Meguiar’s 105 to remove sanding marks.

- Finish with a fine polish, such as 3M Ultrafine Machine Polish, to restore gloss and clarity.

Note: Polishing alone will not remove orange peel. You must level the surface first with wet-sanding. This process takes time and skill. If you are not confident, ask a professional for help.

Weight and Layer Thickness Concerns

You want your motorcycle to stay light and fast. Adding too much paint or clear coat can increase the weight of your carbon fiber fairings. Even a small amount of extra weight can affect how your bike handles and performs. Thick paint layers also act as insulation. This can trap heat and make it harder for your fairings to protect against things like lightning strikes or sudden temperature changes.

When you apply too much clear coat, you risk damaging the carbon fiber underneath. The extra thickness can cause problems like delamination or cracking, especially if your bike faces harsh weather or impacts. Always aim for thin, even coats. This keeps your fairings light and strong. Remember, a lighter bike uses less fuel and feels more responsive on the road. Keep your paint layers as thin as possible for the best results.

Maintenance Tips for Carbon Fiber Paint on Fairings

Cleaning and Care

You want your custom-painted carbon fiber fairings to look sharp and last long. Start by washing them with mild soap and water. Use a soft microfiber cloth or sponge. This method removes dirt without scratching the surface. Rinse with clean water to clear away any leftover soap. Dry the fairings by patting them gently with a microfiber towel. Avoid rubbing, which can cause swirl marks.

Never use harsh chemicals or pressure washers. These can damage the resin and weaken your fairings.

For deeper cleaning, you can use a clay bar. If you see light scratches, polish them out with a mild plastic polish like Meguiar's PlastX. Attach a foam pad to a drill, apply polish, and work at low speed. Always check the surface temperature with your hand to prevent overheating. Repeat the process a few times if needed. This keeps your fairings smooth and glossy, even after customizing carbon fiber parts with custom designs and graphics.

Protecting the Finish

You need to protect your finish from sun and weather. Apply a UV-protectant wax or sealant made for carbon fiber or composites. This step helps prevent yellowing and fading. Store your motorcycle away from direct sunlight and moisture. Use a padded cover when you transport your bike. These habits keep your custom designs on carbon fiber looking new.

Regular inspection helps you spot cracks, chips, or delamination early. Fixing small problems quickly prevents bigger issues.

Touch-Up and Repair Advice

Even with care, you may find chips or scratches on your fairings. For small scratches, use a mild polish and a microfiber applicator. Avoid aggressive buffing or sanding. If you see cracks or signs of delamination, seek professional help. Structural repairs need special skills and tools. Always check your fairings after long rides or track days. This routine helps you keep customizing carbon fiber parts safe and looking great.

Touch up paint chips right away to stop moisture from reaching the carbon fiber. This step extends the life of your fairings and protects your custom designs.

Painting carbon fiber motorcycle fairings becomes easy when you follow each step with care. You choose the right materials and use proper techniques. This approach helps you avoid common problems and gives your bike a strong, glossy finish.

Remember: Regular cleaning and quick repairs keep your fairings looking sharp.

Stay patient and enjoy the results of your hard work!

FAQ

How long does carbon fiber paint last on motorcycle fairings?

You can expect carbon fiber paint to last several years with proper care. Use a quality clear coat and keep your fairings clean. Store your bike away from harsh sunlight to extend the paint’s life.

Can you paint over old carbon fiber paint?

Yes, you can paint over old carbon fiber paint. Sand the surface lightly to remove gloss and clean it well. Apply a compatible primer before adding new paint for the best results.

What should you do if the paint starts peeling?

If you see peeling, stop riding and inspect the area. Sand off loose paint, clean the surface, and reapply primer and paint. Use thin coats to prevent future peeling.

Do you need special tools to paint carbon fiber fairings?

You do not need expensive tools. A good spray gun or quality aerosol cans work well. Use a respirator mask and gloves for safety. Paint in a clean, well-ventilated area.

How do you fix small scratches on painted carbon fiber?

Use a mild polish and a soft microfiber cloth. Rub gently in a circular motion. For deeper scratches, use fine sandpaper, then polish. Always test on a small area first.

See Also

Comprehensive Guide To Understanding Motorcycle Fairings And Design

Effective Tips For Cleaning And Maintaining Motorcycle Fairings

Comparing Leading Carbon Fiber Motorcycle Fairing Brands Today

How To Design Custom Motorcycle Fairings Using Artificial Intelligence

DIY Methods For Making Personalized Motorcycle Fairings At Home